Tool and die makers in India | Plastic Mould Manufacturer

15/1 Rama Road

Kirti Nagar Delhi-110015 India

+91 8883912346

asia@hongyijig.com

Certified

ISO 9001:2015

PRODUCTDEVELOPMENT

INJECTIONMOULD

- INDUSTRIAL DESIGN

- ENGINEERING DESIGN

- PROTOTYPING

- INJECTION MOULDS

PRODUCTDEVELOPMENT

INJECTIONMOULD

- INDUSTRIAL DESIGN

- ENGINEERING DESIGN

- PROTOTYPING

- INJECTION MOULDS

PRODUCTDEVELOPMENT

INJECTIONMOULD

- INDUSTRIAL DESIGN

- ENGINEERING DESIGN

- PROTOTYPING

- INJECTION MOULDS

NEW PRODUCTDEVELOPMENT

FROM INDUSTRIAL DESIGN TO INJECTION MOULDS & BATCH PRODUCTION

KITCHEN APPLIANCES | HOME

APPLIANCES | ELECTRONICS

ENCLOSURES | INDUSTRIAL

PRODUCTS | MEDICAL

COMPONENTS & EQUIPMENTS

COMMODITY | FURNITURE |

AUTOMOTIVEENGINEERING | EVM

MANUFACTURING FEASIBILITY TO

INJECTION MOULDS | PART VALIDATION

AUTOMOTIVE ENGINEERING

COMPONENTS (TIER-1) |

LIGHTNING 4 WHEELERS |

EXTERIOR PANELS | CABLE

PROTECTING COMPONENTS |

ENGINE COVERS | FIXTURES

FMCG[ Packaging and Enclosures ]

HIGH PRODUCTIVE

MULTI CAVITY MOULDS

THIN WALL CONTAINERS |

FOOD CONTAINERS | CAPS &

ENCLOSURES | FLIP TOP CAPS

| CABLES TIES | DOUBLE

COLOUR MOULDS | IMD

MOULDS | CABLES GLENDS

| MULTI CAVITY SOULTIONS |SPRAYS

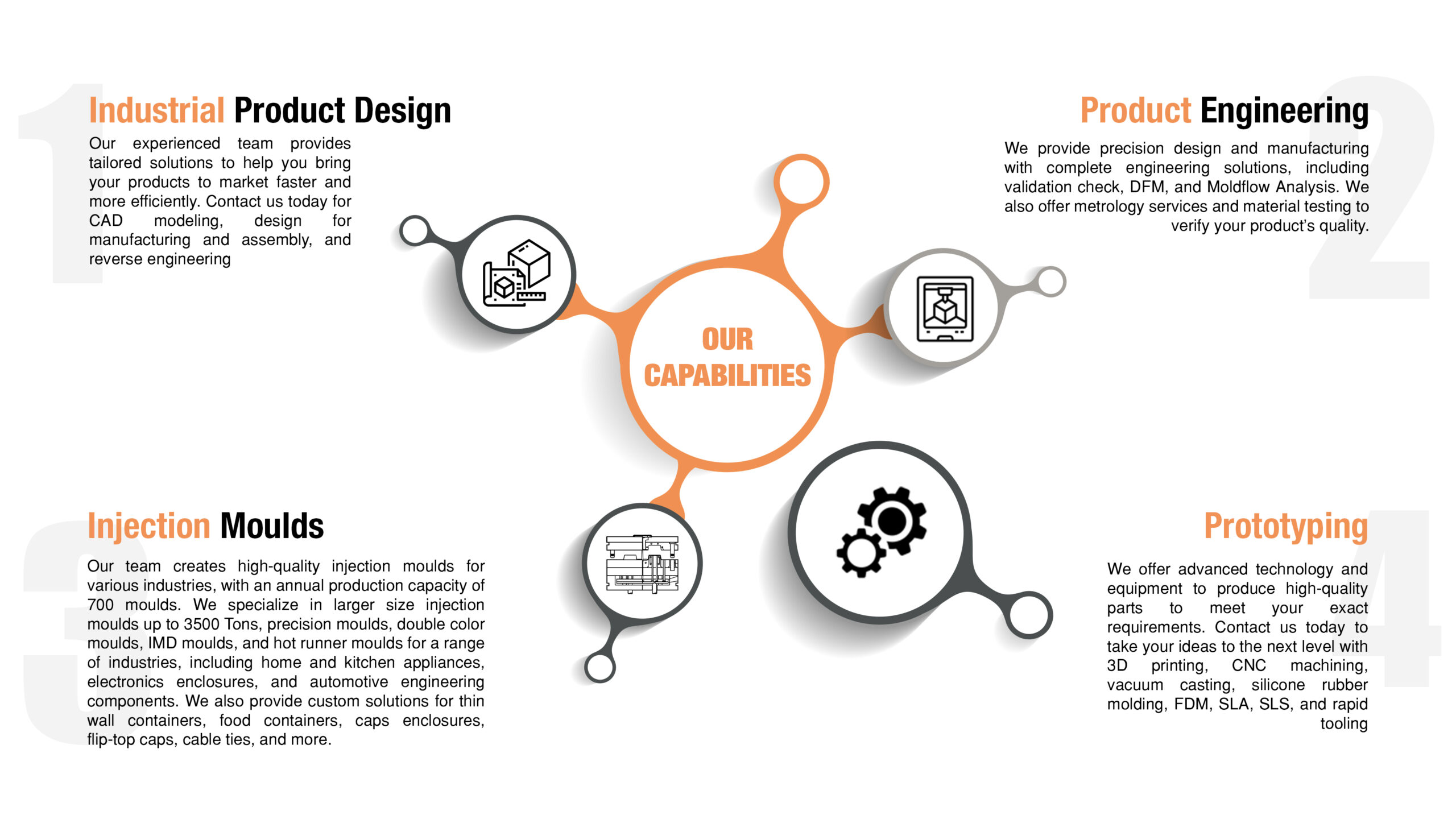

OUR CAPABILITIES

At our company, we offer a range of capabilities to help you bring your product ideas to life. Here’s a quick rundown of what we can do for you

Industrial Product Design

Transforming your vision into reality with innovations

CONCEPT TO CREATION

Our Industrial Product Design and Engineering Services Bring Your Ideas to Life

Industrial product design and engineering design services are crucial for companies seeking a competitive edge in the market. These services cover CAD modeling, design for manufacturing and assembly, and reverse engineering, ensuring cost-effective, functional products. Our experienced team provides tailored solutions to help you bring your products to market faster and more efficiently.

Prototyping And Mockup

Transforming your vision into realitywith innovativeness

DESIGN TO REALITY

Transform your ideas into reality with our cutting-edge prototyping services

We offer prototyping services including 3D printing, CNC machining, vacuum casting, silicone rubber molding, FDM, SLA, SLS, and rapid tooling. Our advanced technology and equipment produce high-quality parts to meet your exact requirements. Contact us today to take your ideas to the next level.

DESIGN TO REALITY

Transform your ideas into reality with ourcutting-edge prototyping services

We offer prototyping services including 3D printing, CNC machining, vacuum casting, silicone rubber molding, FDM, SLA, SLS, and rapid tooling. Our advanced technology and equipment produce high-quality parts to meet your exact requirements. Contact us today to take your ideas to the next level.

Prototyping And Mockup

Transforming your vision into realitywith innovativeness

Industrial Product Design

Transforming your vision into reality with innovations

ENGINEERING WITH PRECISION

Transform Your Product Ideas with Precision Engineering and Quality Assurance

Our Industrial Product Engineering services provide precision design and manufacturing while avoiding warpage and sink marks. We offer complete engineering solutions, including validation check, DFM, and Moldflow Analysis. We also offer metrology services, including reverse engineering and component inspection by CMM, profile projectors, and videography, Material testing to verify your product’s quality.

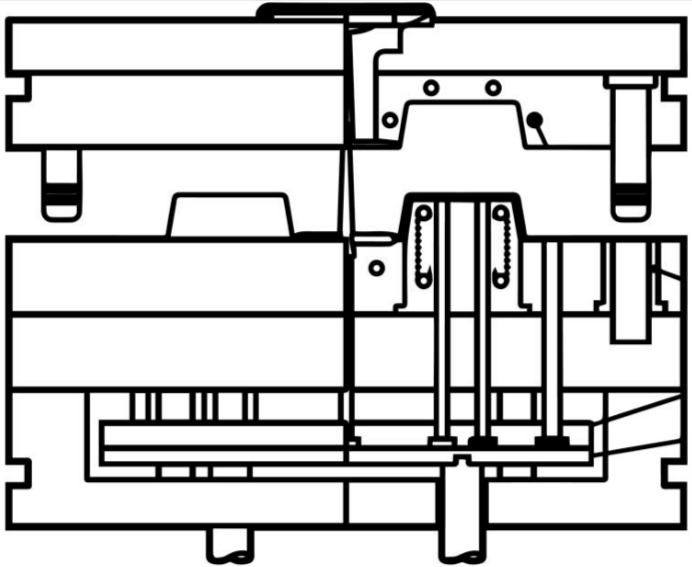

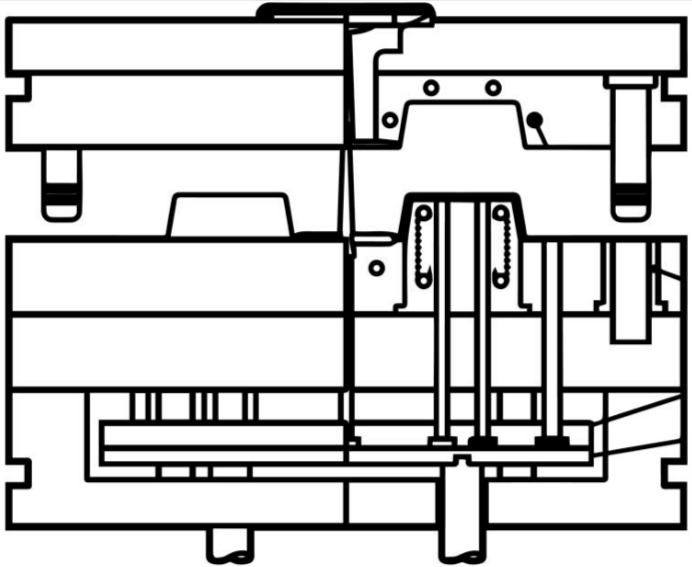

INJECTION MOULDS

Custom solutions Let us bring your product ideas to life

We specialize in high-quality injection moulds for various industries, with an annual production capacity of 700 moulds. Our team creates larger size injection moulds up to 3500 Tons, precision moulds, double colour moulds, IMD moulds, and hot runner moulds for home appliances, kitchen appliances, electronics enclosures, automotive engineering components, automotive exteriors, and more. Also custom solutions for thin wall containers, food containers, caps enclosures, flip-top caps, cable ties, and more

INJECTION MOULDS

Custom solutions Let us bring your product ideas to life

We specialize in high-quality injection moulds for various industries, with an annual production capacity of 700 moulds. Our team creates larger size injection moulds up to 3500 Tons, precision moulds, double colour moulds, IMD moulds, and hot runner moulds for home appliances, kitchen appliances, electronics enclosures, automotive engineering components, automotive exteriors, and more. Also custom solutions for thin wall containers, food containers, caps enclosures, flip-top caps, cable ties, and more

MARKET PRESENCE

MARKET PRESENCE

IMTOS | TAGMA | PLAST ASIAINDIA PLAST | PLAST INDIA

Active participation in every Plastic, Die Mould and Engineering Events and Exhibitions

MARKET PRESENCE

IMTOS | TAGMA | PLAST ASIAINDIA PLAST | PLAST INDIA

Active participation in every Plastic, Die Mould and Engineering Events and Exhibitions

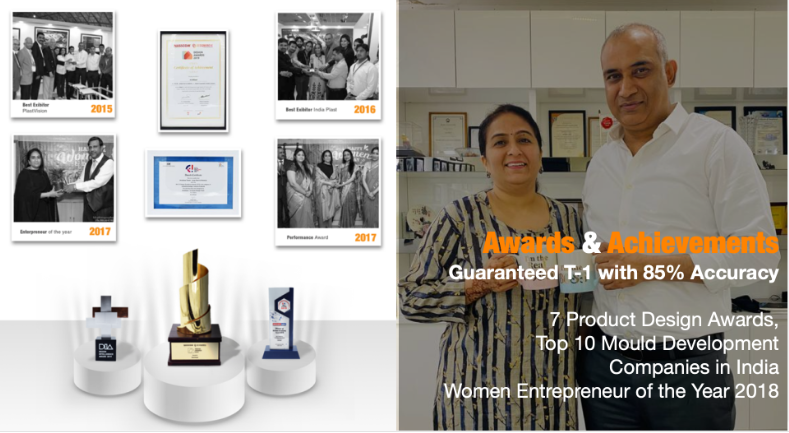

AWARDS & ACHIEVEMENTS

TESTIMONIALS

Words from Our Satisfied Customer

Our Esteemed Customers

We look forward to Serve you as well