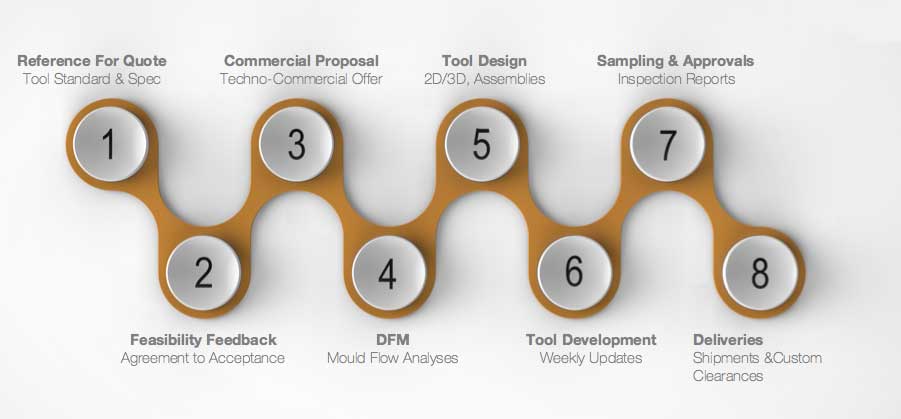

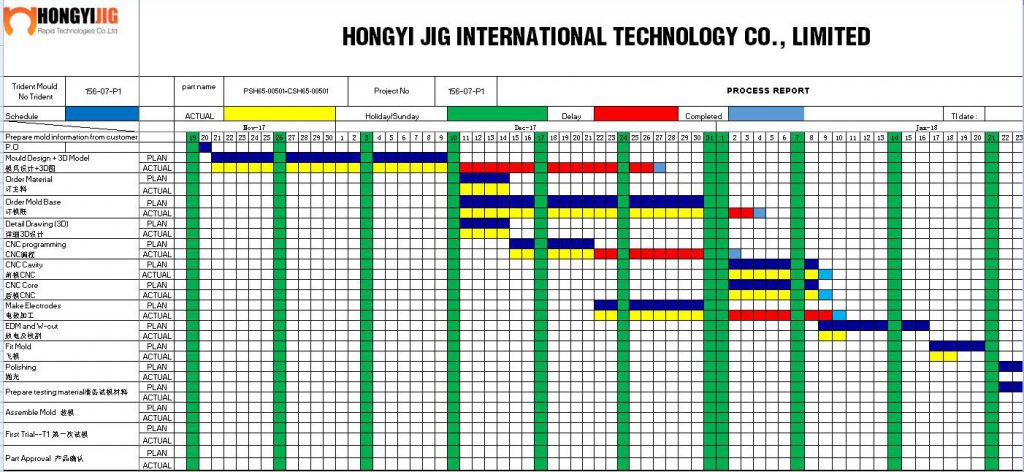

Our Project Engineers can also identify ways to cut-down program lead-times, while also avoiding program pitfalls through early problem detection for which we then work quickly to solve. The result: benchmark improvements for your product quality and process efficiency through total and proactive support for plastic molding engineering.

Plastic Injection Mold Engineering at HJIG is a vitally integrated part of our operation. Our engineering support provides design responsible advantages for mold design and plastic part design at whatever service level is needed. We can provide targeted assistance to support your total turnkey project